Iimveliso

- Carton Printing Slotting Die Cutting Machine

- Umgca weMveliso yeKhadibhodi yeCorrugated

- Flute Laminator Machine

- Ibhedi yeFlat Die yokusika kunye nomatshini wokusika

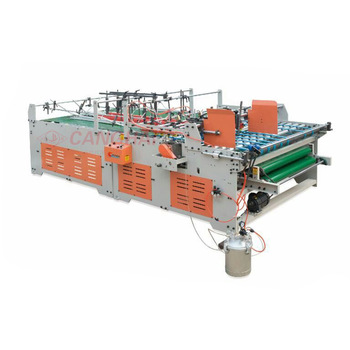

- Umatshini weGluer yeefolda

- Umatshini wokuthunga

- Umatshini wokwenza amanqaku eBlade eNcinci

- I-Slotter yesiNxulumano emine kunye neSisiki seKona

-

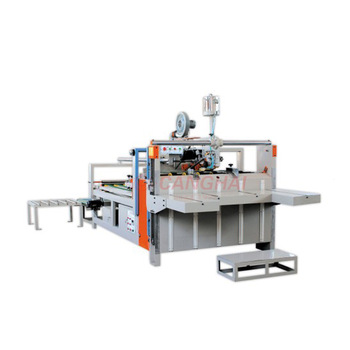

Ikhonkco ezine slotting kunye Corner Cutter

Ifanelekile kwimveliso yebhokisi enye, ephindwe kabini kunye neninzi.

Ubume obubambeneyo, ukusetyenziswa ngokufanelekileyo kunye nokugcinwa. Inxalenye yothumelo yamkele inkqubo yokutshiza yokutshiza, qinisekisa ukuba umatshini uchanekile kwaye usebenzise ubomi.

-

Iblade yombane elungelelanisiweyo uhlobo olucekethekileyo lwe-blade slitter scorer

Umbane ulungelelanise isantya se-slitter blade, ukutshixa kwe-auto pneumatic, kulula ukusebenza, ukuphucula ukusebenza kakuhle.

Isikhokelo se-optical axis kabini, ukusebenza okuzinzileyo;inlay PU ring sela, ecocekileyo kunye nothuli-proof.

Inxalenye yeSlitter: Yamkela umgangatho ophezulu wentsimbi ye-tungsten, ebukhali kunye nobomi obude bomsebenzi, isilayidi sicocekile ngakumbi, singacinezeli kwaye singe-burr.

Inxalenye yamanqaku: thatha amanqaku ama-5 amanqaku, umgama wokufaka amanqaku kwinqanaba lokuhlengahlengisa, i-blazonry kwaye kulula ukugoba iphepha lebhokisi.

I-Adopt 8 shafts design, i-shafts ezimbini ngaphambili nangasemva kwe-slitter, inokunciphisa ubude be-paperboard machining.

Inxalenye yokugaya: Yamkela ngokuzenzekelayo kunye nencwadana yeentlobo ezimbini zodidi lokusila lwe-pneumatic, inokuba kukusila xa usebenza, ukuphucula ukusebenza kakuhle.

Yamkela i-brand edumileyo yaseTshayina okanye into yombane evela kumazwe angaphandle, ukusebenza okuthembekileyo. -

Umatshini wokwenza umatshini wokwenza iBhokisi yeKhathoni eXhotyisweyo

I-interface yomshini womntu-ulawulo lwe-PLC, le nkqubo yinkqubo yokusebenza yerobhothi.Ubuntu obungakumbi, isakhiwo esilula kwaye kulula ukusigcina.1.I-Manual/i-auto feeder iyafumaneka 2.Pre pressing roller,slitting blade and scorerholder are auto adjusted 3.Imela yokusila i-auto/manual 4.Ubukhulu bekhadibhodi kunye namandla ocinezela zilungelelaniswa ngokuzenzekelayo(Ngokuzithandela) 5.Jog ukulungelelanisa kakuhle 6.Umsebenzisi-uchazwe ukuseta umgama weeblades kunye namanqaku 7.Auto counter 8.Slitting kunye nokucofa umgca ngokuchanekileyo ± 0.5mm

-

Semi-auto stitching machine

1. I-Mitsubishi kabini i-servo drive, ukuchaneka ngokuchanekileyo, ukunciphisa iindawo zokuhanjiswa koomatshini, kunokunciphisa ngokufanelekileyo izinga lokungaphumeleli komatshini.

2. I-Weilun touch screen operation, iiparameters (umgama wezikhonkwane, inani lezikhonkwane, uhlobo lwezikhonkwane, ipaneli yangasemva) tshintsha ngokukhawuleza nangokulula.

3. Yonke inkqubo yokulawula isebenzisa inkqubo yokulawula i-Omron PLC yaseJapan.

4. I-baffle yombane yangasemva iqhutywa yi-motor stepping, kwaye ubungakanani buchanekile, kwaye ubungakanani bulungele ngakumbi kwaye bukhawuleza.

-

Carton Box Stapler Stitching Machine

Umzi-mveliso wethu ngumsebenzi ovelisa i-DXJ Stitch.Umatshini weDXJ uyilwe ngokwenzuzo yohlobo olufanayo lweemveliso eziveliswe kuyo

ekhaya naphesheya.Intloko yomatshini yakhiwe ngeegiya eziphindwe kabini ze-eccentric ukuze zisebenze kunye: i-angle yoxinzelelo ithatha isitayile sofakelo esilungele ukusikwa kocingo kunye nokutshintshana.

-

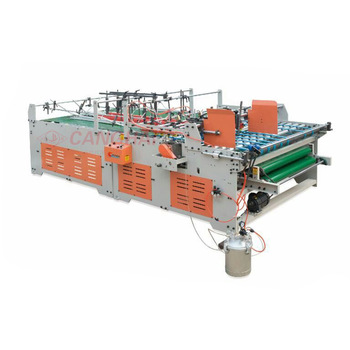

Iziqwenga ezibini zoMatshini weGluer wekhadibhodi

I-1.Iyunithi yokutya yomshini ine-stack yebhodi yephepha ezimbini zokubamba i-AB ezimbini zamaphepha, ezinceda ukuphucula ukusebenza kakuhle kwemveliso.Ngezantsi yamkela isakhiwo sokufunxa umoya, esilungele ukuphucula ukuthutha kunye nokuchaneka.

I-2.Iyunithi yokudibanisa ithatha i-adhesive ye-melt eshushu, i-gauge ye-side gauge positioning, iqinisekisa irejista echanekileyo kunye nokuchaneka okuphezulu.

3.Iyunithi yokugoba ithatha ukugoba ngesandla, okusombulula ingxaki yobunzima bokuqinisekisa indawo yokugoba.Umda we-overlap unokulawulwa ngokufanelekileyo.

4.Umatshini unokuqhutywa ngabantu ababini.Omnye upakisha amaphepha kwaye uqokelele umsebenzi ogqityiweyo. Omnye usonge amaphepha kwaye uwafake kwibhanti yokucinezela.Umatshini wonke usebenza lula.

-

I-ZXJ-B Semi-Automatic Gluer

I-ZXJ-B yohlobo lwe-semi-automatic umatshini webhokisi encamathelayo kule minyaka yamva nje ukuveliswa kwebhokisi yezixhobo ezitsha zokusingqongileyo, ngakumbi ukunamathela kwebhokisi, ukulahla indlela yokubopha izikhonkwane zobhedu, ukuphucula ukusebenza kakuhle kwemveliso, i-ChanPinXing esemgangathweni.

Isakhelo esiphambili: isakhelo, ukuphakamisa indawo yokusebenzela, izixhobo zokuhambisa, izixhobo zokuhambisa phakathi kutshanje, uxinzelelo kunye nesixhobo, isixhobo esigqityiweyo semveliso yecala eliphakathi, izixhobo zokulawula umbane.

-

Umatshini wegluer we-semi-automatic

Umatshini wokuncamathelisa we-RS uphuhliselwe imfuno yomthengi, uhlala kwindawo encinci Kulula ukusebenza ngaphandle kobuchule: umatshini ulungile ekuveliseni iodolo encinci, kunye nokutshintsha ucwangco.Ukusetyenziswa ngokubanzi: ibhokisi eqhelekileyo, ibhokisi yombala engaqhelekanga eyibhodi enye kwibhokisi, ukuba umatshini wongeza isixhobo sokutshiza seglu, umatshini unokuncamathelisa ibhokisi esezantsi yeHook kunye nebhokisi yekona ezine Ukugcina imathiriyeli: imathiriyeli ibe yi-1/ I-3 yokuncamathelisa ngesandla.Ukugcina abasebenzi: Isantya esikhulu somatshini yi-56m/min, amaxesha angama-3-4 wokuncamathelisa ngesandla I-gluing eqinile, icocekile ngaphandle kokuchitha impahla: izixhobo zokusila kabini zinokusila indawo yokudibanisa ukuze kucace ifilimu ye-UV okanye enye iplastiki yokuphucula amandla eglu, kunye nokusombulula.

-

Tshixa iQhosha Uhlobo lweKhathoni Yebhokisi Yokwenza Umatshini

Semi-automatic ifolda yegluer enomzantsi wokutshixa isetyenziselwa ukupakisha, ishishini lokuhombisa, ukuSonga iibhokisi. Umatshini ukuya kwizinti, icala elincangathi ubukhulu becala, Ukusuka kwiphepha lokutya, ukugoba, ukuncamathelisa iglu, i-homing eyenziweyo ukucofa ukubumba ibhokisi, ukuphumeza iingenelo zokuzenzekelayo kunye nokusebenza ngesandla kuyancedisana

-

Umatshini weGluer ozenzekelayo weFolda

AutomaticFmdalaGluer ikakhulu isetyenziselwa iibhokisi zebhokisi yokupakisha iibhokisi zamashishini, inkqubo yeebhokisi zokubopha.Oku kungenxa yokuba uninzi lwamashishini asekhaya kwindawo yokupakisha ekhethekileyo kunye nebhokisi yebhokisi yebhokisi yebhokisi yebhokisi yentsimbi yokuncamathisela iinkqubo zokwenziwa zisetyenziswa ngokusulungekileyo, nto leyo ekhokelele ekuncamathiseleni kweenkqubo zokubumba iibhokisi kwishishini, ngakumbi kumashishini okuvelisa iibhokisi zamathala asebenzisa kakhulu, egubungela uninzi. , ubuncinci bokusebenza.

-

uhlobo oluzenzekelayo lwesemi

(1) Yamkela i-nodular cast iron-QT500-7, i-mainframe wallboard casting yinkqubo ekhethekileyo yeteknoloji, ngaloo ndlela ibonisa amandla aphezulu, ungalokothi uguqule kwaye uqinisekise ukhuseleko lwebhodi enkulu yodonga.

(2) Yamkela i-Taiwan-imported mechanism yethutyana yokuqinisekisa ukuba umatshini usebenza ngokuchanekileyo kwaye unciphise ukwenzeka kwezinga lokungaphumeleli.

-

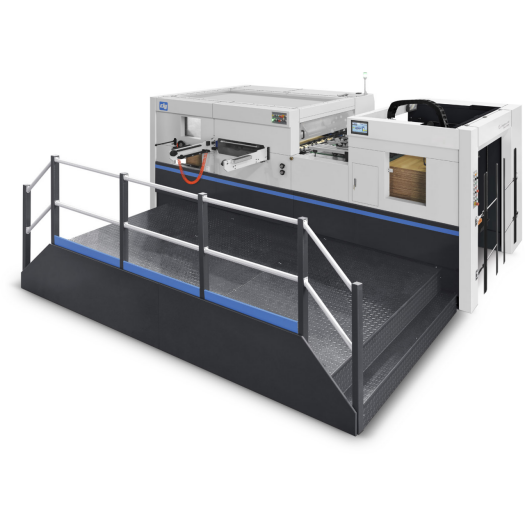

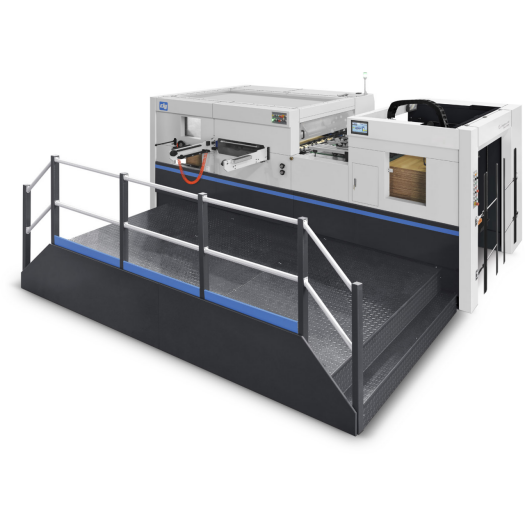

Uhlobo oluzenzekelayo lweBhokisi yoKwenza umatshini

Isizukulwana sesine seMHC Series Automatic Manual Die Cutting Machine (Tiptronic Die Cutting Machine) esekelwe kwisizukulwana sesithathu seSemi-automatic Die Cutting Machine kunye neFront Conveyor Delivery Mechanism, ixhotyiswe nge-feeder ezenzekelayo, kuquka zombini ukutyisa iphepha kunye nephepha elizenzekelayo. umsebenzi wokutyisa.Kwimeko yephepha elithathiweyo elisicaba, ukutyiswa kwamaphepha okuzenzekelayo kwamkelwe ngokunyusa ukusebenza kakuhle kunye nokunciphisa abasebenzi.